It funny, there is no mention of drilling one of the seat back channels into place with the seat back. And when I say no mention... nothing the manual, nothing in the HBH videos, nothing in the Matronics archives. Here is a method for drilling 7F6-5 into place that I used:

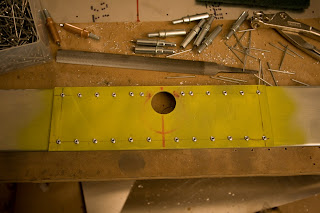

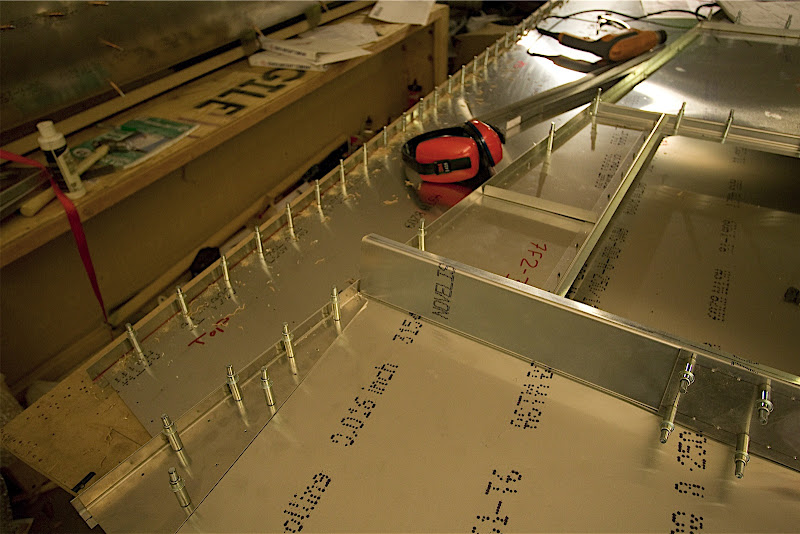

It funny, there is no mention of drilling one of the seat back channels into place with the seat back. And when I say no mention... nothing the manual, nothing in the HBH videos, nothing in the Matronics archives. Here is a method for drilling 7F6-5 into place that I used:First, finding the notes in the plans was hard, so it is A4, pitch 40.

Don't worry about drilling it into the extrusion gusset yet. Draw your centerline on the flange that meets the seat back and push into place. I had one hole on the side extrusion that I had to match, but you are lucky you can just drill the flange into the uprights. Once the back support is positioned, extend the center line onto the uprights.

Cleco the seat back into place over 7F6-5. Now extend the centerline from the uprights onto the seat back. Now space your rivets making sure to take into account where the vertical ("L") will go in the seat back.

I drilled four test holes to make sure I had extended the line properly, which I had. The remaining holes were then drilled.

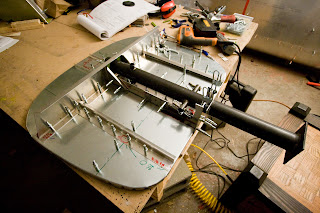

I also had to trim the bottom tabs of the engine mount for a good fit. Sadly the radius bend in the lower mount is causing fit issues. the solution may be shims, grinding away part of the frame rails, or both.

Here are some pictures detailing the issue.

PROGRESS:

Fuselage ~148h ( 3h, 3h, 2h, 3h, 7h, 2h, 5h, 2h, 3h, 2h, 2h, 3h, 6h, 2h, 2h, 1.5h, 2.5h, 1h, 2h, 3h, 2h, 3h, 4h, 1h, 2h, 1h, 3h, 4h, 3h, 3h, 4h, 3h, 4h, 4h, 6h, 3h, 3h, 4h, 2h, 2h, 2h, 4h, 2h, 2h, 10h, 4h, 4h, 6h)

Wings: ~157.5h ( 1h, 1h, 0.5h, 2.5h, 4h, 1h, 1.5h, 1h, 1.5, 4.5, 1h, 1h, 2h, 4h, 1h, 3h, 1h, 2h, .5h, 1.5h, 2h, 2h, 2h, .5h, 1h, .5h, .5h, 2h,3h, 1h, 3h, 3h, 4h, 2h, 3h, 7h, 3h, 1h, 4h, 1h, 1h, 1h, 4h, 2h, 2h, 2h, 2h, 1h, 2h, 3h, 2h, 1h, 3h, 2h, 2h, 1h, 2h, 3h, 2h, 1h, 1h, 1.5, 2h, 2h, 3h, 2h, 1h, 3h, 2h, 1h, 2h, 1h, 5h, 2h, 1h, 2h, 4h, 2h )

Flaperons: ( DONE! ) 23.5 hours spent ( 3h, 1h, 1h, 1h, 1.5h, 3h, 6h, 3h, 4h, 1h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~410h