Has anyone had the following problem?

I'm starting my elevator/stab hinges and noticed a difference between the builder's manual, the plans and the manufactured piece supplied by Zenith concerning the Center Hinge Bracket ( 7H3-3SP ).

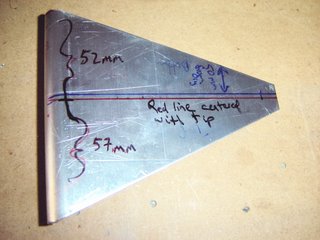

Using the plans I measured 50mm into the flange to make a mark to draw the perpendicular line. This line was off center with the bracket tip by about 2mm. The builders manual states that the line should be centered with the tip.

When tried to figure out why this was and I realized that the flange was 109mm in length, not 107mm as stated in the plans.

Since these measurements are enclosed by boxes on the plans, I assume they are critical, especially since being off will cause problems with the elevator's movement.

Is it better to use the tip center to determine the line knowing that one side of the piece was manufactured 2mm to long, possibly grinding down that side? ( my guess )

Or would it be better to use the line drawn 50mm in? ( seems like that would weaken the hinge )

Update 1: I think that the piece was cut wrong AND that the flange was bent in the wrong direction.

Update 2: Zenith is sending me a new piece. Thanks to Caleb and Nick for their support.

Project Status:

Elevator: ~20 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h )

Horizontal Stabilizer: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder Done, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~65 hours