We spent about three hours measuring and drilling the right inboard flaperon skeleton. The skeleton is now riveted, minus the splice rib.

Project Status:

Flaperons: ( right outboard, left outboard DONE! ) 15.5 hours spent ( 3h, 1h, 1h, 1h, 1.5h, 3h, 6h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~95 hours

Saturday, September 30, 2006

Monday, September 25, 2006

The air compressor came back from the shop... and since it was still crammed into the back of a Jeep we decided to use the hand riveter to finish the flaperon half. A nail got stuck in the riveter and all attempts to get it out have failed.

We started the right inboard half and got as far as getting the pieces out and placing them on the pre-drilled skin.

Project Status:

Flaperons: ( right outboard, left outboard DONE! ) 12.5 hours spent ( 1h, 1h, 1h, 1.5h, 3h, 6h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~92 hours

We started the right inboard half and got as far as getting the pieces out and placing them on the pre-drilled skin.

Project Status:

Flaperons: ( right outboard, left outboard DONE! ) 12.5 hours spent ( 1h, 1h, 1h, 1.5h, 3h, 6h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~92 hours

Sunday, September 17, 2006

We spent about 1.5 hours building Saturday... a grill that is. The building experience of the CH701 is much easier compared to a Char-Broiled grill. Seriously.

We spent about 1.5 hours building Saturday... a grill that is. The building experience of the CH701 is much easier compared to a Char-Broiled grill. Seriously.In my never-ending campaign to justify the expense of the Garmin 496 a little bit of aerial recon was performed... on pumpkin patches. We flew up and down the surrounding farm lands looking for patches, and when we found one that looked good we marked the location. The plan is to simply use to GPS to navigate us there in a few weeks. In 1.5 hours of flying we covered the same amount of ground that a whole day's worth of driving would take.

Friday, September 15, 2006

We spent another hour on the left outboard flaperon. The splice rib and associated bracket were drilled into place, the whole assembly was deburred and then protected from corrosion. The splice rib and bracket were riveted into place using the hand riveter.

After some exploration the electric drill does not differ from the air drill in regards to producing burrs. The electric drill is less ideal than the air drill in three main ways. 1) The chuck area is larger and thus much harder to get into tight spaces. 2) The drill is MUCH heavier so when it punches through the metal the chuck hits the metal skin with more force, and thus the protective rubber washers much faster and it is much easier to damage the skin. 3) The drill takes a long time to spool down after use making several seconds of delay required before moving onto the next hole. On the upside the drill generates much less noise.

Project Status:

Flaperons: ( right outboard DONE! ) 11.5 hours spent ( 1h, 1h, 1.5h, 3h, 6h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~91 hours

After some exploration the electric drill does not differ from the air drill in regards to producing burrs. The electric drill is less ideal than the air drill in three main ways. 1) The chuck area is larger and thus much harder to get into tight spaces. 2) The drill is MUCH heavier so when it punches through the metal the chuck hits the metal skin with more force, and thus the protective rubber washers much faster and it is much easier to damage the skin. 3) The drill takes a long time to spool down after use making several seconds of delay required before moving onto the next hole. On the upside the drill generates much less noise.

Project Status:

Flaperons: ( right outboard DONE! ) 11.5 hours spent ( 1h, 1h, 1.5h, 3h, 6h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~91 hours

Wednesday, September 13, 2006

Slow progress this week due to outside issues including a weekend drive to Eugene.

The bottom of of the left outboard flaperon is riveted. The top was drilled using the new electric drill. The new drill has a very different feel in it's operation. The drill spools up, sits on the metal for a second and then instantly sinks into the metal. The time to spool down the drill takes much longer than the air drill. I haven't deburred yet, so I will not know how using a high RPM / low torque drill will vary in respect to the high torque . lower RPM air drill. My guess is that the holes will be cleaner.

Another building tip about the flaperons: The trailing edges are pre-drilled. The builder's manual says that the top edge of the flaperon may not reach the trailing edge, and just to trim the extra off. The problem is that the pre-drilled holes prevent this and trimming would ruin the skin!

So besides exercising extreme caution in the measuring of the ribs to make the bottom skin match up, I found an interesting technique to make the top skin "work".

After ratcheting down the skin with 2x2's, I slowly used some silver clecos in the trailing edge to "pull" the pre-drilled holes together. Initially it was hard to find holes close enough to start the process and it took another person to help pull and push the skin.

Project Status:

Flaperons: ( right outboard DONE! ) 10.5 hours spent ( 1h, 1.5h, 3h, 6h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~90 hours

The bottom of of the left outboard flaperon is riveted. The top was drilled using the new electric drill. The new drill has a very different feel in it's operation. The drill spools up, sits on the metal for a second and then instantly sinks into the metal. The time to spool down the drill takes much longer than the air drill. I haven't deburred yet, so I will not know how using a high RPM / low torque drill will vary in respect to the high torque . lower RPM air drill. My guess is that the holes will be cleaner.

Another building tip about the flaperons: The trailing edges are pre-drilled. The builder's manual says that the top edge of the flaperon may not reach the trailing edge, and just to trim the extra off. The problem is that the pre-drilled holes prevent this and trimming would ruin the skin!

So besides exercising extreme caution in the measuring of the ribs to make the bottom skin match up, I found an interesting technique to make the top skin "work".

After ratcheting down the skin with 2x2's, I slowly used some silver clecos in the trailing edge to "pull" the pre-drilled holes together. Initially it was hard to find holes close enough to start the process and it took another person to help pull and push the skin.

Project Status:

Flaperons: ( right outboard DONE! ) 10.5 hours spent ( 1h, 1.5h, 3h, 6h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~90 hours

Thursday, September 07, 2006

The compressor is in the shop. For future reference: Do not buy an "oil less" air compressor. They are loud and light duty.

We bought a 2500RPM VSR drill for about $60 to hold us over. Unfortunately using the hand riveter takes about 10x longer than the pneumatic riveter.

The Matronics Kitfox list has been abuzz about LED lighting, and I am convinced this is the way to go, and I will probably follow this guys instructions: http://www.itsys3.com/kitfox/discover.shtml The current plan is still to use a Dynon Flightdek D180, the Garmin 496, a single com and a transponder. Light, sleek, modern.

We bought a 2500RPM VSR drill for about $60 to hold us over. Unfortunately using the hand riveter takes about 10x longer than the pneumatic riveter.

The Matronics Kitfox list has been abuzz about LED lighting, and I am convinced this is the way to go, and I will probably follow this guys instructions: http://www.itsys3.com/kitfox/discover.shtml The current plan is still to use a Dynon Flightdek D180, the Garmin 496, a single com and a transponder. Light, sleek, modern.

Monday, September 04, 2006

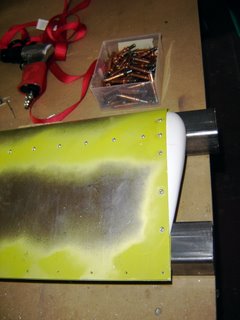

We spent about 6 hours today on the flaperons..

We spent about 6 hours today on the flaperons..One major build tip for these is when riveting the skeleton, rivet the hinge extrusions last so you have some extra play to sneek the rivet gun to the hole.

Another major tip is to wait to drill and place the splice rib and associated angle. We placed and drilled the angle first and then got major "beer canning" when ratcheting over the top of the skin.

The fiberglass tips fit somewhat poorly. You can even see this is the builder's manual. I played with them for a while and did my best. There is a little gap between the bend in the skin, but it shouldn't matter.

The compressor decided to die today while we were making major progress. At first it wouldn't stop the compressor when it reached 150 psi. Then it wouldn't compress past 120 psi, then 100 psi. Finally we heard a very loud "pop"/"bang" like a firecracker from the compressor followed by a doubling of it's pitch. I shut it off, unplugged it and then drained it's air pressure by using it. I got about half of the bottom of the left outboard flaperon riveted. Luckily we have the hand riveter, but no electric drill.

Project Status:

Flaperons: ( right outboard DONE! ) 10.5 hours spent ( 1.5h, 3h, 6h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~89 hours

Sunday, September 03, 2006

We finally found some time to get back on the project. Between work, friends and the trip to Eugene something had to give.

We finally found some time to get back on the project. Between work, friends and the trip to Eugene something had to give.The right outboard flaperon is coming along quickly. We almost made a deadly mistake a SECOND time... drilling mounting brackets upside down. The holes for the brackets already existed in the skin and cause me to double check my measurements and positions.

My guess is that we have maybe two hours more work on the piece. The left outboard flaperon should take less time, and the inboards seem to be a similar process.

If I can get part of Labor day, one night during the week and one day next weekend, all four pieces should be done by Sept 17. The slats shouldn't take much time, so the wings and tanks need to be ordered soon.

Project Status:

Flaperons: 4.5 hours spent ( 1.5h, 3h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~83 hours

Subscribe to:

Posts (Atom)