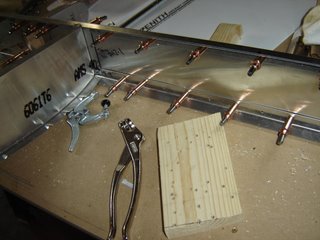

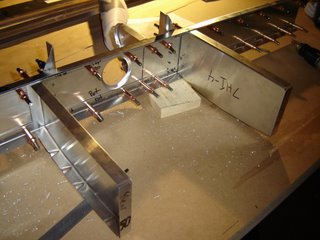

After much organizing of the workshop, and taking of the inventory, work finally began on N701MH again. It has been several months since taking the workshop at Quality Sport Planes so the memory needed to be jogged a bit. Two sessions were done, the first lasting 3 hours, the second for two hours.

Cutting the thick aluminum brackets (7H2-6) took forever with the hacksaw. I have a high speed cutting tool, but the chuck is missing. The hack saw took at least 30 minutes alone. So far I am still happy with the kit, it seems to be about on par with the rudder kit, but I can not determine why those pieces would not have come already cut.

I was going to fly the C150 around, but found that the spinner was dented and scraped. I'm not sure how un balanced a dented spinner would make the propeller, so anyone with an idea please chime in. There are two likely scenarios 1) Another plane hit the spinner while parking 2) The fuel service truck damaged it.

UPDATE:

Two A&Ps took a look at the spinner and determined that the piece is still airworthy and that the damage is only superficial. The next time I have an oil change they will take off the spinner and reshape it. The scratches may have been caused by my engine block plug's "REMOVE BEFORE FLIGHT" warning label during a wind storm we had in Seattle several days prior.

Project Status:

Horiztonal Stabilizer: 5 hours spent ( 3h, 2h )

Rudder Done : ~16 hours spent ( 8h, 8h )

Worshop Done: ~8 hours

1 comment:

I don't know much about aviation beyond the rudiments of Bernoulli's Principle, but my gut feeling is that any part that is out of spec should probably be replaced with one that isn't. When you're up at 10,000 feet it would be nice to know that all your parts met or exceeded the prescribed standards.

Post a Comment