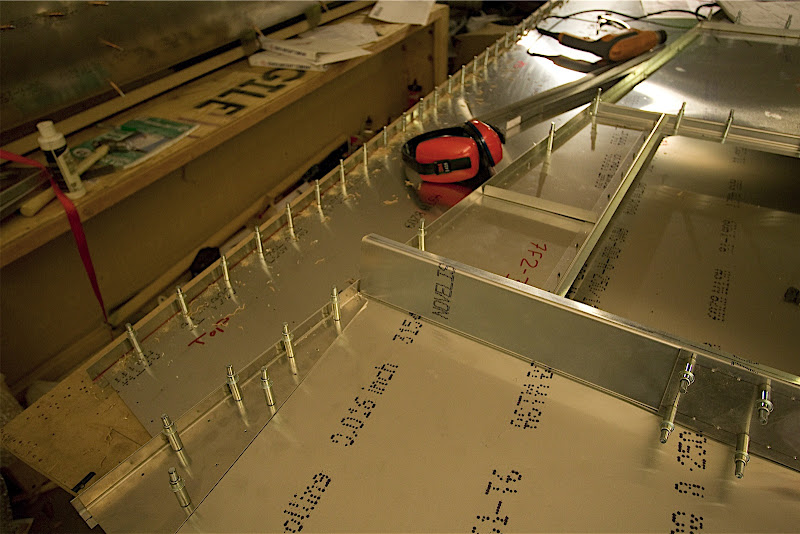

Saturday five hours were spent. The big highlight was the mis-matched ("L") angle. I'm still trying to decide what to do about that. Besides that, the rear hole doubler was put in place, the sides and top skins were mated and the bulk heads were drilled into place on the pilot side and top.

Saturday five hours were spent. The big highlight was the mis-matched ("L") angle. I'm still trying to decide what to do about that. Besides that, the rear hole doubler was put in place, the sides and top skins were mated and the bulk heads were drilled into place on the pilot side and top.The fuselage is squared up.

On Saturday two hours were spent once again on the CNC error, and getting the interior gussets into place. The gussets still need to be trimmed.

Also, I am considering adding some extra ("L") angle to reduce the "audio slip indicator":

Fuselage ~27h ( 3h, 3h, 2h, 3h, 7h, 2h, 5h, 2h )

Wings: ~157.5h ( 1h, 1h, 0.5h, 2.5h, 4h, 1h, 1.5h, 1h, 1.5, 4.5, 1h, 1h, 2h, 4h, 1h, 3h, 1h, 2h, .5h, 1.5h, 2h, 2h, 2h, .5h, 1h, .5h, .5h, 2h,3h, 1h, 3h, 3h, 4h, 2h, 3h, 7h, 3h, 1h, 4h, 1h, 1h, 1h, 4h, 2h, 2h, 2h, 2h, 1h, 2h, 3h, 2h, 1h, 3h, 2h, 2h, 1h, 2h, 3h, 2h, 1h, 1h, 1.5, 2h, 2h, 3h, 2h, 1h, 3h, 2h, 1h, 2h, 1h, 5h, 2h, 1h, 2h, 4h, 2h )

Flaperons: ( DONE! ) 23.5 hours spent ( 3h, 1h, 1h, 1h, 1.5h, 3h, 6h, 3h, 4h, 1h )

Paint Design: 2 hours spent ( 1h, 1h )

Elevator DONE!: ~31.5 hours spent ( 3h, 1.5h, 3h, .5h, 3.5h, 2h, 4h, 1.5h, 2h, 4.5h, 1h, 6h )

Horizontal Stabilizer DONE!: ~28 hours spent, 3 pieces replaced ( 3h, 2h, 2h, 2h, .5h, 1.5h, 3.5h, 1.5h, 5, 4.5, 2h, .5h )

Rudder DONE!, minus horn : ~16 hours spent, ( ~8h, ~8h )

-----------------------

Total Done: ~286h